Heat - From Concern to Crisis - Igniting Action for a Cooler Building with Thermal Insulation and Ventilation Solutions

Introduction:

In the scorching heat of summer, industrial complexes and factory buildings often turn into veritable ovens, trapping heat within their confines and making work environments uncomfortable, if not unbearable. The rising temperatures not only affect the productivity of workers but also pose significant challenges to the structural integrity of the buildings themselves. However, amidst this concern lies an opportunity for proactive measures to tackle the heat issue head-on. By leveraging advanced solutions such as Thermal Insulated Roofing Sheets and strategically placed Metal Louvers for ventilation, industrial facilities can transform from heat traps to havens of comfort and productivity.

We will look into the solutions that can tackle heat issue in the building

1. Understanding the Heat Conundrum

2. Thermal Insulated Roofing Sheets

3. Strategic Ventilation Solutions

6. Integration for Optimal Performance

Understanding the Heat Conundrum:

Before delving into the solutions, it's essential to understand the root of the heat problem in industrial buildings. These structures are often characterized by large, open spaces with expansive roofs that absorb and retain heat, creating a greenhouse effect. Without proper insulation and ventilation, this trapped heat can escalate from a mere concern to a full-blown crisis, impacting worker well-being, equipment efficiency, and overall operational costs.

Enter Thermal Insulated Roofing Sheets:

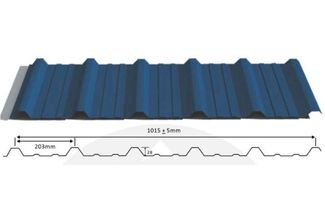

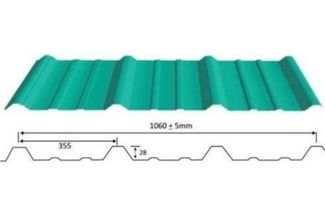

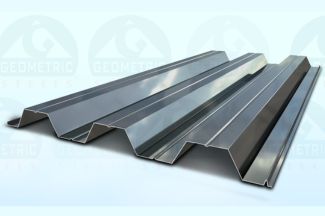

The first line of defence against excessive heat build-up in industrial buildings is thermal insulation. Traditional roofing materials, such as metal sheets, conduct heat with alarming efficiency, exacerbating the indoor temperature. However, with advancements in technology, the advent of Thermal Insulated Roofing Sheets has revolutionized the way buildings manage heat transfer.

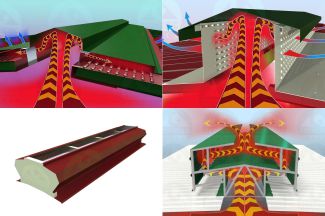

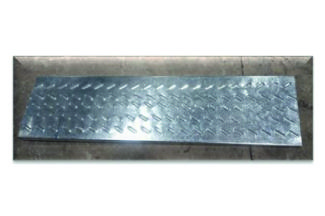

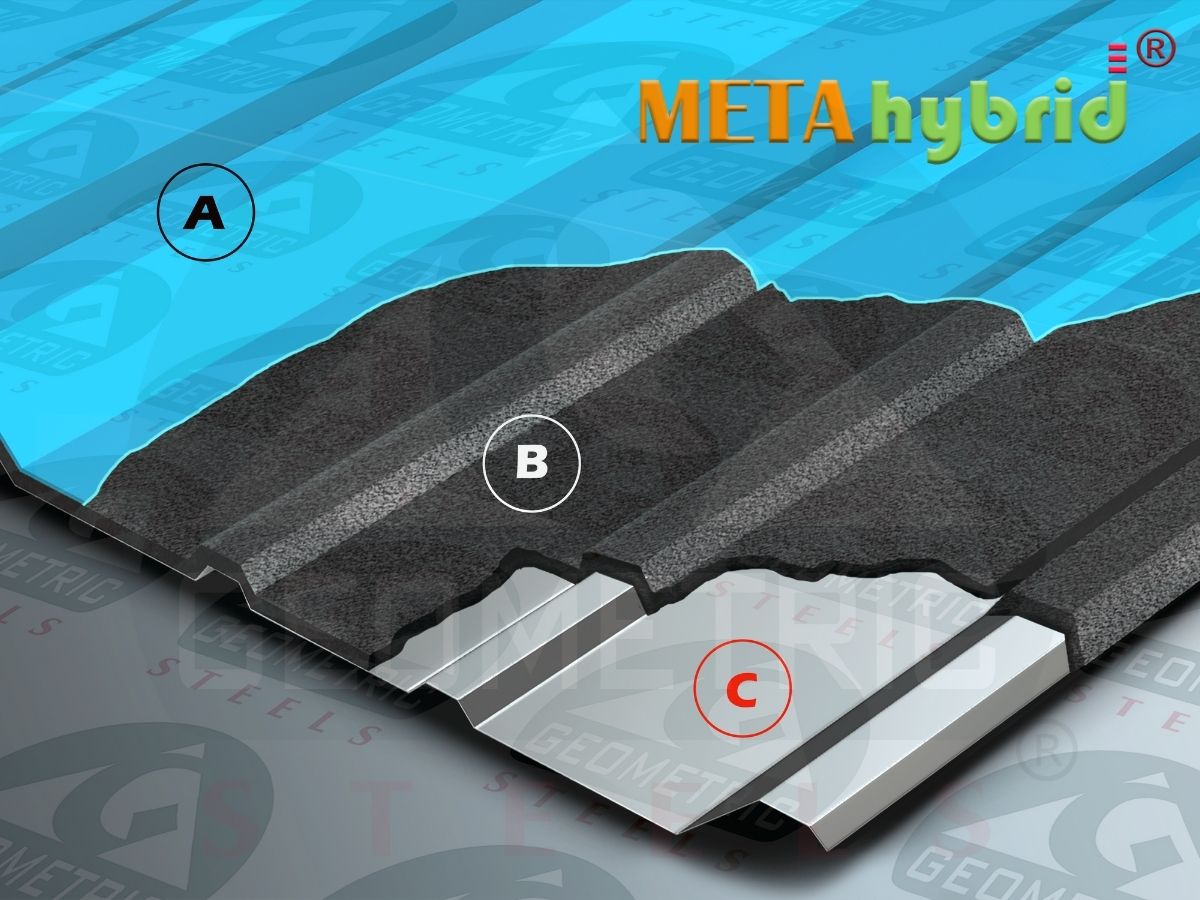

Thermal Insulated Roofing Sheets are engineered to provide superior insulation properties, effectively minimizing heat gain during the day and heat loss at night. The construction of these sheets typically consists of multiple layers, each serving a specific purpose in enhancing thermal performance. The top layer is a durable metal profile sheet, providing structural integrity and weather resistance. Beneath it lies a unique thermal insulation material, designed to impede the flow of heat through the roof assembly. Finally, a bottom layer, often aluminium foil or another metal sheet, completes the sandwich structure, ensuring optimal thermal efficiency.

Benefits of Thermal Insulated Roofing Sheets:

1. Reduced Heat Transfer: By significantly reducing heat transfer through the roof, Thermal Insulated Roofing Sheets help maintain comfortable indoor temperatures, even in the face of scorching external conditions.

2. Energy Savings: By minimizing the need for mechanical cooling systems, insulated roofing sheets contribute to substantial energy savings, lowering operational costs and environmental impact.

3. Enhanced Durability: The robust construction of insulated roofing sheets not only improves thermal performance but also enhances the longevity and resilience of the building envelope, reducing maintenance requirements and lifecycle costs.

4. Improved Comfort: With better temperature regulation, workers experience improved comfort and productivity, fostering a more conducive working environment.

5. Compliance with Regulations: As energy efficiency regulations become increasingly stringent, opting for Thermal Insulated Roofing Sheets ensures compliance with industry standards and future-proofs the building against evolving requirements.

Strategic Ventilation Solutions:

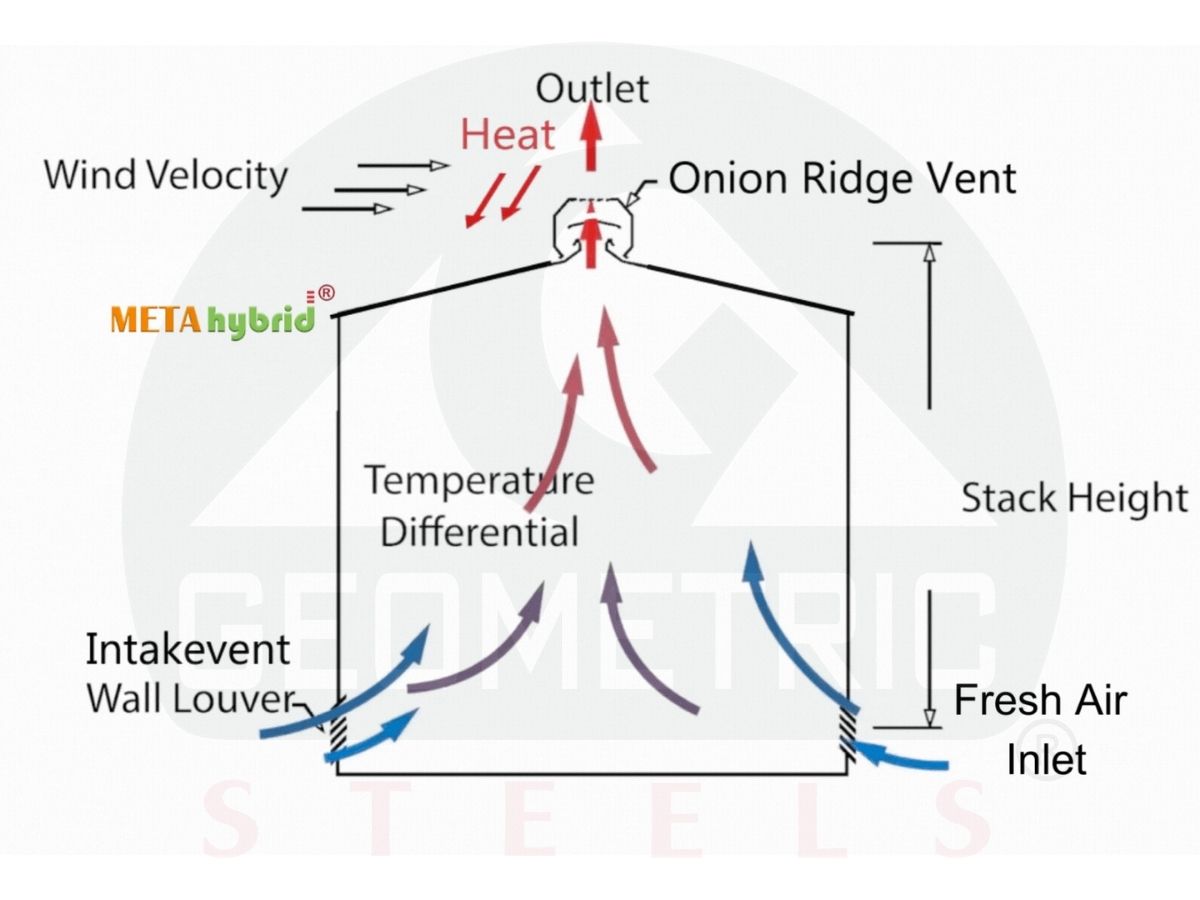

While insulation forms the foundation of heat management, effective ventilation plays an equally crucial role in maintaining optimal indoor conditions. Industrial buildings require a constant influx of fresh air to replace stagnant, overheated air and mitigate the build-up of humidity and pollutants. This is where strategically placed Metal Louvers and Ridge Vents come into play.

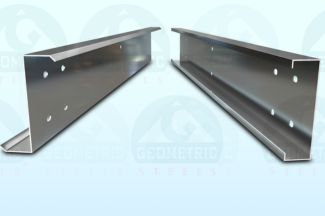

Metal Louvers:

Metal Louvers serve as intake vents, allowing fresh air to enter the building while expelling hot air and pollutants. Available in various configurations to suit different applications, these louvers are strategically positioned along the perimeter of the building to facilitate natural airflow.

Benefits of Metal Louvers:

1. Fresh Air Intake: By facilitating the entry of fresh outdoor air, Metal Louvers improve indoor air quality, promoting a healthier and more comfortable environment for occupants.

2. Heat Dissipation: As hot air rises within the building, Metal Louvers provide an outlet for its expulsion, preventing the build-up of heat and maintaining consistent temperatures throughout the space.

3. Moisture Control: Proper ventilation helps mitigate the accumulation of moisture, reducing the risk of mold growth, structural damage, and corrosion of equipment.

4. Energy Efficiency: By harnessing natural ventilation principles, Metal Louvers minimize reliance on mechanical HVAC systems, resulting in significant energy savings and reduced carbon emissions.

5. Customizable Options: From residential to industrial applications, Metal Louvers offer a range of customizable options to meet specific airflow requirements and aesthetic preferences.

Ridge Vents:

Complementing the intake provided by Metal Louvers, Ridge Vents serve as exhaust vents, allowing hot air to escape from the highest point of the building. Installed along the ridge line of the roof, these vents leverage the natural process of convection to facilitate the upward movement of air.

Benefits of Ridge Vents:

1. Efficient Heat Exhaust: By venting hot air trapped in the upper reaches of the building, Ridge Vents promote passive cooling and prevent the formation of heat pockets, ensuring uniform temperature distribution.

2. Enhanced Air Circulation: The continuous exchange of indoor and outdoor air facilitated by Ridge Vents maintains optimal humidity levels and prevents the stagnation of air, creating a more pleasant and productive environment.

3. Weather Resistance: Constructed from durable materials and engineered for maximum weather resistance, Ridge Vents withstand the rigors of harsh climatic conditions while providing reliable long-term performance.

4. Quieter Operation: Unlike mechanical exhaust systems, Ridge Vents operate silently, minimizing noise pollution and preserving the tranquillity of the work environment.

5. Sustainable Solution: By harnessing natural airflow and reducing reliance on energy-intensive cooling methods, Ridge Vents contribute to sustainability efforts and support green building initiatives.

Integration for Optimal Performance:

While Thermal Insulated Roofing Sheets, Metal Louvers, and Ridge Vents each offer significant benefits on their own, their true potential is realized when integrated into a cohesive system designed for optimal performance. By strategically combining these elements and leveraging their complementary attributes, industrial facilities can achieve unparalleled comfort, energy efficiency, and operational resilience.

Case Study:

Geometric Steels Factory Transformation To illustrate the transformative impact of integrated thermal insulation and ventilation solutions, let's examine the case of Geometric Steels, a leading manufacturer of roofing and construction materials. Faced with escalating heat-related challenges in their production facilities, Geometric Steels embarked on a comprehensive retrofitting project aimed at enhancing thermal comfort and operational efficiency.

Step 1: Thermal Insulation Upgrade. The first phase of the transformation involved retrofitting the existing roofing system with state-of-the-art Thermal Insulated Roofing Sheets. By replacing traditional metal sheets with insulated panels, Geometric Steels significantly reduced heat transfer through the roof, resulting in a more stable and comfortable indoor environment.

Step 2: Ventilation Enhancement Building upon the foundation of thermal insulation, Geometric Steels implemented a strategic ventilation strategy incorporating Metal Louvers and Ridge Vents. By strategically positioning intake louvers along the building perimeter and exhaust vents at the ridge line, the company achieved optimal airflow dynamics, effectively dissipating excess heat and maintaining fresh indoor air quality.

Step 3: Performance Monitoring and Optimization To ensure continued efficacy and performance, Geometric Steels implemented a comprehensive monitoring and optimization program, leveraging advanced sensors and analytics tools to track indoor temperature, humidity levels, and airflow patterns in real-time. By proactively identifying areas for improvement and fine-tuning system parameters, the company maximized energy efficiency and operational resilience.

Results and Benefits: transformative impact of Geometric Steels' integrated thermal insulation and ventilation solution was profound, yielding a host of tangible benefits across various facets of their operations:

1. Enhanced Worker Comfort:Employees reported a significant improvement in thermal comfort, with reduced instances of heat-related fatigue and discomfort, leading to higher morale and productivity.

2. Energy Savings:By minimizing reliance on mechanical cooling systems, Geometric Steels realized substantial energy savings, resulting in lower operational costs and reduced environmental footprint.

3. Extended Equipment Lifespan: The controlled indoor environment facilitated by the integrated solution mitigated the risk of equipment overheating and premature failure, extending the lifespan of critical assets and reducing maintenance expenses.

4. Regulatory Compliance:By adhering to stringent energy efficiency standards and sustainability guidelines, Geometric Steels positioned itself as a responsible corporate citizen and gained a competitive edge in the marketplace.

5. Future-Ready Infrastructure:With a robust, future-proof infrastructure in place, Geometric Steels is well-equipped to adapt to evolving environmental regulations and market dynamics, ensuring long-term viability and success.

Conclusion:

As the global climate continues to evolve, the need for sustainable and resilient building solutions has never been more pressing. By proactively addressing the heat challenge through the adoption of advanced thermal insulation and ventilation technologies, industrial facilities can mitigate risks, enhance operational efficiency, and create healthier, more comfortable environments for their workforce. With innovation, collaboration, and a commitment to excellence, the journey from heat concern to crisis becomes an opportunity for transformation and progress.